-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

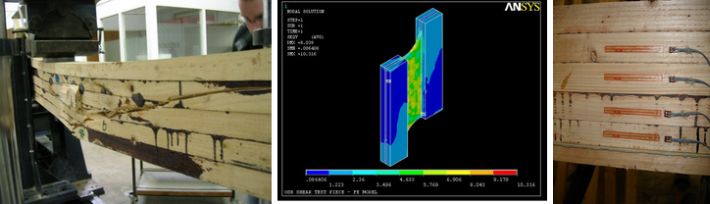

Facilities

This laboratory and research group have a range of testing machines and equipment at their disposal both in the timber research laboratory and from other facilities based in NUI, Galway. These facilites include both experimental and computational facilities. A brief description of the most important items are given below:

Experimental Facilities:

1. Dartec 500 kN Servo Hydraulic Testing Machine:

This machine is the primary testing machine in the laboratory and is associated with the following features:

- 500kN load capacity.

- An adjustable cross-head which gives a variable daylight of up to 3.5m

- Ram travel of 450m within daylight.

- Test bed length of 7m.

- Interchangeable platens and loading frames.

- Capabilities for both load and displacement control tests.

- Easy manipulation so that tension testing, compression testing and shear testing can be carried out.

- Three and four point bending test capability.

- Dartec 9500 Controller.

- Static and dynamic test capability.

Although this machine was purchased primarily for the timber laboratory it is in regular use by researchers and undergraduate students in other sections within the department.

2. Dartec 250kN Servo Hydraulic Testing Machine:

The Dartec 250kN has the following features:

- 250kN load capacity.

- An adjustable cross-head which gives a variable daylight of up to 1.5m.

- Interchangeable platens and loading frames.

- Capabilities for both load and displacement control tests.

- Infeed and outfeed roller tables of 3.5m length.

- Easy manipulation so that tension testing, compression testing and shear testing can be carried out.

- Three and four point bending test capability.

- Computerised data acquisition.

3. Timber Stress Grading Machine (Cook-Bolinders):

The timber laboratory boasts a Cook Bolinder stress grading machine. Mechanical strength grading is essential in the selection of quality timber for the construction industry and is fundamental in structural timber design.

Mechanical grading is a much faster process than visual grading and is carried out by testing a property or properties non-destructively. The procedure certifies that the timber piece is associated with the desired strength and stiffness characteristics for the application for which it is required.

The current European standard, EN 14081-4 (2005) specifies that a preset deflection based on the species, board thickness and width, is inputted for the grading machine. The load required to obtain this deflection is recorded for both sides of the board and the mean value for each location is determined. The grading procedure involves passing the board between the loadcell and support rollers such that bending is induced about its minor axis, turning it over and passing it through again.

The machine has the features as listed below:

- Computerised rejection of boards which fail to obtain the required structural grade.

- Computerised data acquisition.

- Test span of 900mm.

- Third point (centre point) loading.

- Flatwise bending stiffness readings at 100mm intervals.

- Computerised automatic rejection of boards that do not obtain the required structural grade.

- Infeed and outfeed roller tables of 3.5m length.

4. Timber Beam Press:

The press was specially designed and fabricated so that glue laminated timber beams can be manufacted in the laboratory.

5. Conditioning Chamber:

Features of the conditioning chamber include:

- Temperature and humidity controlled environment.

- Volume: 7m x 4m x 3m.

- Storage of up to 7m long members.

- Easily accessible for deliveries.

Temperature is generally maintained at a temperature of 20±2 oC and relative humidity of 65±5% in accordance with EN 408 -4 Timber structures. Structural timber and glued laminated timber. Determination of some physical and mechanical properties. In general these conditions result in a nominal 12% moisture content for softwoods when checked with an electronic moisture (protimeter timbermaster) using both deep and short probe attachments.

Miscellaneous

To complement the above, the laboratory has a range of LVDTs, timber strain gauges, load cells, calibration equipment and temperature/humidity sensors.

The laboratory also has access to the Department of Civil Engineerings workshop, which is equipped with a wide range of milling and cutting machinery.

Computational Facilities:

The computation facilities in the department comprise of two components primarily.

- State of the art hardware and software for data acquisition and for advanced engineering analysis.

- Finite element software including ANSYS, ABAQUS and Lusas.

Finite element modelling of timber and engineered wood components requires particular expertise. Timber is a complex material to numerically model because of the anisotropy behaviour it exhibits as well as the variability that exists in the material as a result of the high number of inhomogeneities that are randomly present. Furthermore, it is a heterogeneous material and problems are further complicated by its inherent nonlinear characteristics.

Finite element analysis is a particularly useful tool in predicting the structural behaviour and performance of timber and is therefore considered a significant factor in increasing safety during the structural design process.

|